Water Monitoring in Aircraft Refuelling Operations

Effective water detection during aircraft refuelling operations is crucial for ensuring flight safety and fuel quality. Water contamination in aviation fuel can lead to serious engine malfunctions and operational inefficiencies.

ISOIL provides advanced solutions for monitoring and managing water levels in fuel, thereby enhancing both safety and performance.

This article will explain:

- How to ensure Safe and Efficient Aircraft Refuelling;

- ISOIL Advanced Solution to detect and control Water Contamination in Aviation Fuel

How to ensure Safe and Efficient Aircraft Refuelling

When it comes to aircraft refueling, water is a dangerous contaminant that can both compromise safety and reduce efficiency.

Monitoring water content in jet fuel is therefore an essential step of the refuelling procedures requiring specific and suitable equipment.

ISOIL Advanced Solution to detect and control Water Contamination in Aviation Fuel

ISOIL designs and produces specific refueling systems for the aviation sector, intended to ease operations and grant safety in all stages of the procedures.

VEGA T2 is the up-to-date flow computer designed for into plane refuelling operations.

Besides performing all the measurement metrology functions and interfacing to the OBC on the vehicle, VEGA T2 monitors several devices on board of the vehicle itself.

All the information collected are made available to the user by simply accessing a transaction log file, via serial line, ethernet port, Wi-Fi, or to the remote control system via serial / ethernet port with the most common protocols Modbus TCP and RTU.

Among the several devices on the vehicle, VEGA T2 can monitor the water content measure provided by the EWS (Electronic Water Sensor) mounted on board of the vehicle.

More and more vehicles are equipped with this type of device, and dedicated features have been developed specifically on VEGA T2, according to the JIG Bulletin No. 130 dated 20/08/2020, Appendix 2, Para. EWS Warning Light, Check Level Actions, Alarm Level Actions.

The EWS (such as AFGUARD® by FAUDI) can be used to check proper functioning of the Filter Water Separators or to measure the quantity of water in Jet Fuel. The sensor typically provides a 4÷20 mA signal output proportional to the water content.

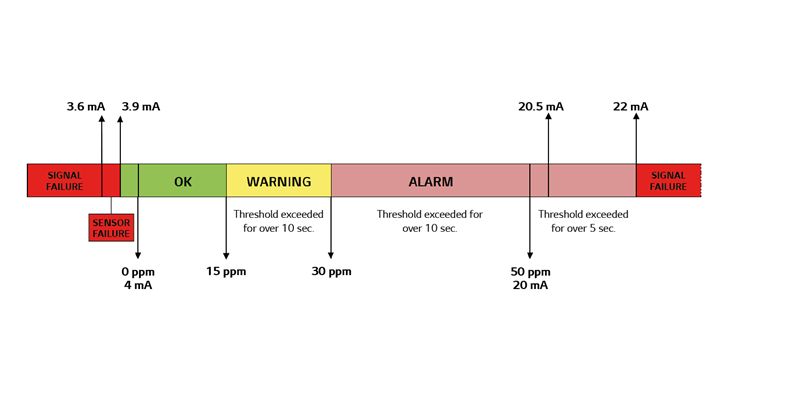

VEGA T2 receives as input the output from the AFGUARD® and converts the signal into a reading in ppm (parts per million), monitoring its value by comparison to two programmable thresholds.

Threshold 1

When the ppm of water is higher than the programmed value (typically 15 ppm for 10 seconds) the dedicated alarm is activated.

Threshold 2

When the water inside the Jet Fuel is higher than the programmed value (typically 30ppm for 10 seconds and 50ppm for 5 seconds) the dedicated alarm is activated.

Alarm generated by this threshold can be reset by a password or by the signal “Lockable reset alarm” (to be chosen by parameter).

Each one of the two thresholds can be enabled/disabled and programmed:

- to set after how many seconds after delivery start, VEGA T2 has to check the ppm value

- to set how long the value can be over the threshold before activating the alarm.

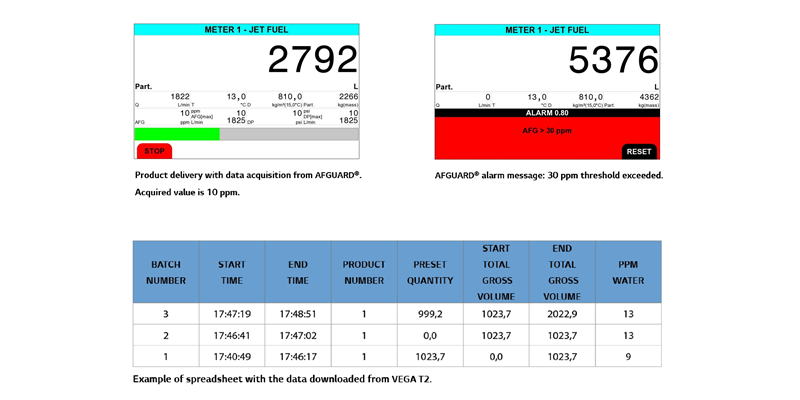

The ppm value of water can be displayed at all time on the VEGA T2.

Weighted average value of the delivery is worked out for each transaction and stored into a log file.

VEGA T2 also calculates the maximum registered value during loading process (peak value) and the corresponding observed flow-rate.

Data can be shown on display, printed and transmitted to an On Board Computer (OBC).

A dedicated ‘blue lamp’ is activated by VEGA T2 during product delivery and it blinks with different frequencies and meanings, when the programmed thresholds are exceeded.

The scheme below summarizes this feature.

® AFGUARD is a Faudi Aviation Registered trademark.

Contact us for more information about our services and products

Form sent successfully

Error